0

0

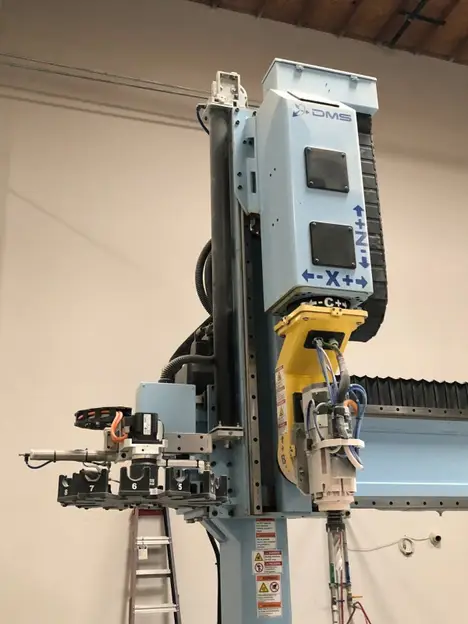

DMS Model 5T5-5-10-48 S CNC Router, New 2017

3603453

10383

ended

CNC Router and Composite Machines from Custom US Auto Manufacture

Online Auction

auction

Verified Seller

Auction Lot Ended

Location:

Logistics:

Rigging:

Loading:

Shipping:

Preview

More Assets From This Auction

See EventPin Carousel

Description

Terms

| Name | DMS Model 5T5-5-10-48 S CNC Router, New 2017 |

|---|---|

| Aucto ID | 2 |

| Manufacturer | DMD |

| Model | 5T5-5-10-48S |

| Additional Info | 2017 DMS MODEL 5T5-5-10-48T DUAL 5′ X 10′ MOVING TABLE, 5 AXIS CNC ROUTER, 48″ Z

2017 DMS MODEL 5T5-5-10-48T 5′ X 10′ 5 AXIS MOVING TABLE CNC ROUTER, 48″ Z

LIKE NEW 2017 DMS 5 X 10 DUAL TABLE (5X10) 5 AXIS ROUTER

48″ Z

TOOL CHANGER

MANUFACTURER LITERATURE:

FAGOR 8055 CNC CONTROLLER:

FAGOR 8055I POWER SERIES FEATURES: INDUSTRY STANDARD MACHINE TOOL CONTROLLER WITH INTEGRATED PLC; FULLY COMPATIBLE WITH ALL CAD/CAM SOFTWARE 5 AXIS POST PROCESSOR NC CODE OUTPUT FILES, ISO G&M CODE, HIGH LEVEL AND PARAMETRIC PROGRAMMING INSTRUCTIONS; HIGH SPEED BLOCK PROCESSING (<1 MS) WITH 200 BLOCK LOOK AHEAD; 11” LCD COLOR MONITOR, 1 MB BASE PROGRAM MEMORY, 512 MB. COMPACT FLASH HARD DRIVE; TOOL PATH SIMULATION GRAPHICS; TELEDIAGNOSTICS; WINDOWS OS SOFTWARE, TCP/IP ETHERNET CONNECTION, USB PORT AND SERIAL PORT. MAIN ELECTRONICS CABINET IS MOUNTED ON THE MACHINE STRUCTURE WITH FILTERED 2000 BTU AIR CONDITIONER.

X AXIS:

X IS THE 60” TABLE WIDTH. MAXIMUM TRAVEL IS 72 INCHES. MAXIMUM FEEDRATE IS 1500 INCHES PER MINUTE. TRACKWAYS ARE PRECISION PROFILED WITH SEALED LINEAR BEARING BLOCKS. FIXED LEADSCREW IN PRELOADED TENSION WITH SERVO DRIVEN SPINNING BALLNUT.

Y AXIS:

Y IS THE 120” TABLE DEPTH. MAXIMUM TRAVEL IS 132 INCHES. MAXIMUM FEEDRATE IS 1500 INCHES PER MINUTE. TRACKWAYS ARE PRECISION PROFILED WAYS WITH SEALED LINEAR BEARING BLOCKS. FIXED LEADSCREW IN PRELOADED TENSION WITH SERVO DRIVEN SPINNING BALLNUT.

Z AXIS:

Z AXIS TRAVEL AND BRIDGE CLEARANCE FROM THE TABLE IS 36 INCHES STANDARD (48″ OPTIONAL) . MAXIMUM FEEDRATE 800 INCHES PER MINUTE. TRACKWAYS ARE PRECISION PROFILED WAYS WITH SEALED LINEAR BEARING BLOCKS. ROTATING LEADSCREW SERVO DRIVEN WITH ANGULAR CONTACT BEARINGS.

ROTARY AXES:

VIRTUAL ZERO BACKLASH HIGH REDUCTION RATIO PRECISION GEAR DRIVES. B AXIS PIVOTS PERPENDICULAR TO THE TABLE – TRAVEL LIMITS ARE +/- 120 DEGREES. PIVOT DISTANCE FROM SPINDLE FACE TO B ROTATION POINT IS APPROXIMATELY 9”. C AXIS ROTATES PARALLEL TO THE TABLE – STANDARD ROTATION IS +/- 363 DEGREES. B&C MAXIMUM ROTATIONAL SPEEDS ARE 135 DEGREES PER SECOND.

DRIVE SYSTEMS:

CLOSE LOOP BRUSHLESS AC SERVO MOTORS WITH DIGITAL DRIVERS ON ALL AXES.

CUSTOMER REQUESTED OPTIONS:

Z AXIS STROKE: 48” Z AXIS STROKE & BRIDGE CLEARANCE

FIXTURE HOLD DOWN: THREADED INSERTS (3/4” – 16) ON 12×12 INCH CENTERS.

VACUUM VALVE: AUTOMATIC SOLENOID OPERATED VACUUM VALVE. 1-3/4” VACUUM HOSE CONNECTION. ON/OFF CONTROL VIA PROGRAM M-CODE, OPERATOR PANEL AND TABLE PUSHBUTTONS.

SPINDLE – 12 HP ISO30 TOOLING: HSD 12 HP MODEL ES929 QUICK TOOL CHANGE SPINDLE. TOOLHOLDERS ARE AVAILABLE IN ER32 COLLET (3/4” MAX TOOL) AND ER40 COLLET (1” MAX TOOL) STYLES. AC FREQUENCY INVERTER CONTROLS PROGRAMMABLE SPEED RANGE FROM 2000 TO 20000 RPM. ELECTRONIC SPEED BRAKE. SPINDLE IS FAN COOLED.

AUTOMATIC TOOL CHANGER: 12 POCKET TRAVELING CAROUSEL TOOL MAGAZINE. THE CAROUSEL IS SERVO DRIVEN AND PNEUMATICALLY ACTUATED INTO POSITION BY THE CONTROLLER.

AUTOMATIC TOOL LENGTH SENSOR: DMS PRECISION SENSOR. MACRO PROGRAM AUTOMATICALLY SELECTS TOOL FROM MAGAZINE, MEASURES LENGTH AND STORES THE VALUE IN THE FAGOR CNC TOOL OFFSET TABLE.

TOOLING PACKAGE: QTY. (8) ISO30 SIZE ER32 TOOLHOLDERS & COLLET ASSORTMENT; TIGHTENING FIXTURE; ER32 SPANNER WRENCH.

FAGOR 8055 CONTROLLER UPGRADE: INCLUDES CPU TURBOPROCESSOR FOR HIGHER SPEED SIMULTANEOUS MULTI-AXIS POSITIONING. TOOL CENTER POINT PROGRAMMING (TCP) WITH 5 AXIS TOOL LENGTH COMPENSATION AND UPGRADE TO 2 GB. COMPACT FLASH FOR INCREASED PART PROGRAM STORAGE CAPACITY.

SERVO DRIVE SYSTEM: FAGOR SERCOS DIGITAL DRIVE SYSTEM INCLUDING FAGOR SERVOMOTORS.

JOG HANDWHEEL/ TEACH PENDANT: HAND HELD UNIT PROVIDES REMOTE HAND WHEEL OPERATION IN JOG MODE AND BASIC POINT TO POINT TOOL PATH DIGITIZING DURING TEACH IN MODE. THE DEVICE INCLUDES A HAND WHEEL AXIS SELECT, INCREMENT SELECT, DIGITIZING FEATURES AND REMOTE FEEDRATE OVERRIDE CONTROL.

ELECTRONICS COOLING: 2000 BTU A/C UNIT. SEALED NEMA 12 DUST TIGHT CABINET.

INPUT POWER: SEALED TRANSFORMER FOR 440-460 VAC 3 PH. OPERATION.

AUTO LUBE: PROGRAMMABLE AUTOMATIC DISTANCE METERED LIGHT OIL FEED TO ALL LINEAR AXIS BALLNUTS AND BEARING BLOCKS. |

Shop with Confidence

Exclusive inventory from trusted brands

US & Canada based support team

Transparent pricing. No hidden fees!

Door-to-door shipping

Interface directly with equipment owners

No lead times

Secure payment options

Fair & transparent bidding